SLUG CATCHER PRODUCT LINE

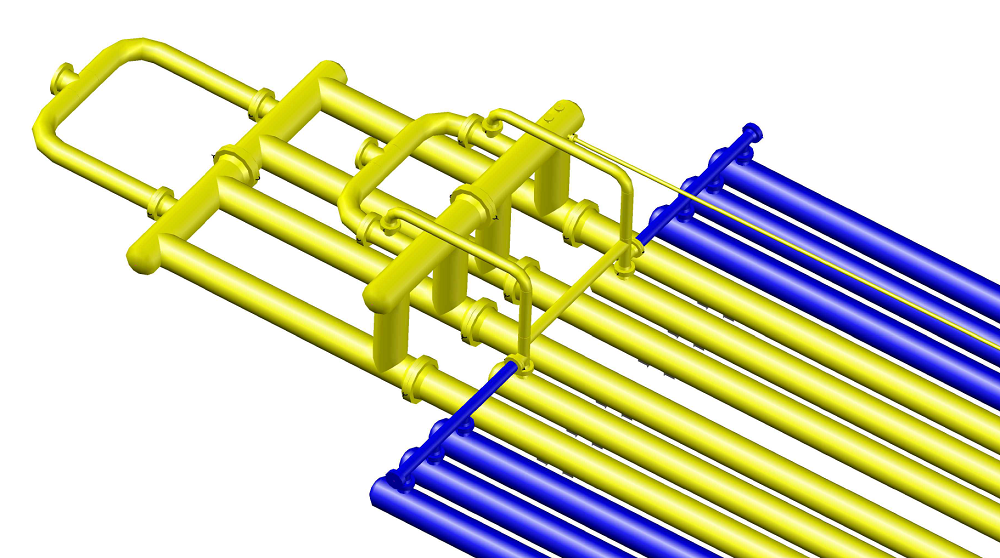

Holloman is a one stop shop for harp (finger), hybrid, and vessel slug catchers. We pride ourselves on providing the lowest total installed cost (TIC) for harp/finger type slug catcher installations. Holloman’s standard harp design keeps constructability as a central focus, achieving the lowest installed cost possible. With deep construction experience in building harp slug catchers—we know that construction costs can often exceed the initial purchase price of other competitor’s “go build it yourself” designs. By utilizing shop prefabrication to create shippable modular sections, excessive field welding and other areas of costly field construction are eliminated.

Holloman’s standard harp design utilizes readily available high yield pipe and fittings in a sophisticated design arrangement to keep the purchase price and lead time to a minimum. This is accomplished without use of proprietary extrusions or contoured outlet fittings, which are necessary for many of our competitors to produce their designs.

Holloman’s standard harp designs are compact and make efficient use of space. Generally speaking, the longer the harp the better and our standard harp offering achieves the greatest economy per BBL at 300-600 ft in length.

Holloman’s standard harp designs can be configured in a variety of ways using modular sections. The standard harp design’s window of performance covers gas flows of 50 MMSCFD to 2.5 BSCFD and liquid storage from 500 BBL to 40,000 BBL. Fingers are typically constructed from 36″, 42″, 48″, 54″, or 60″ pipe. Larger designs can be custom engineered.

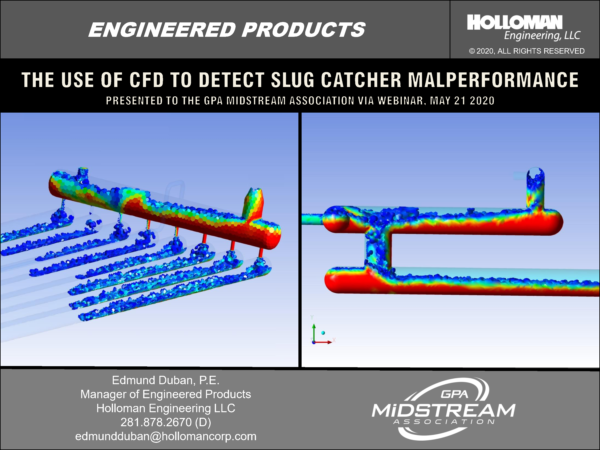

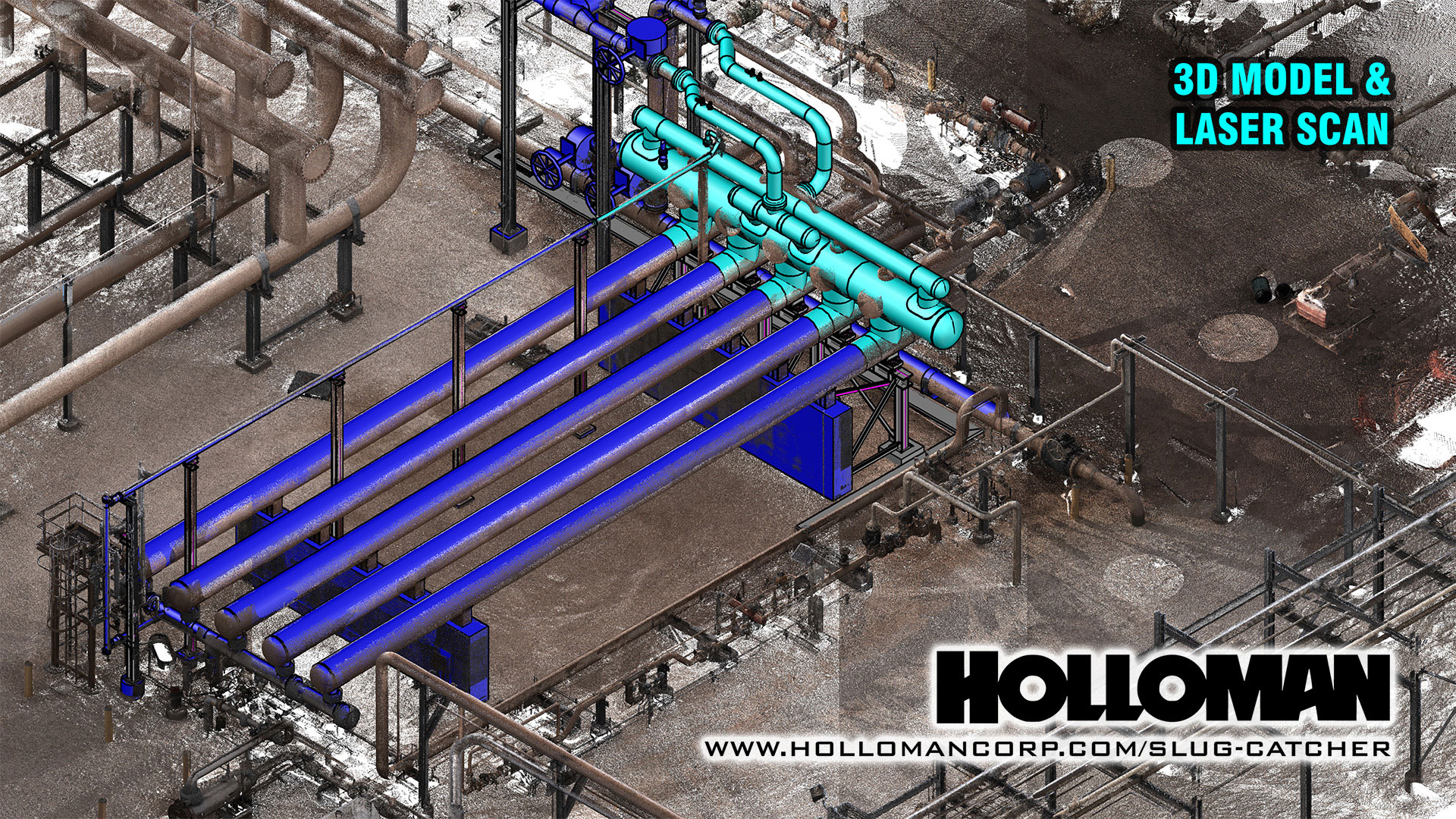

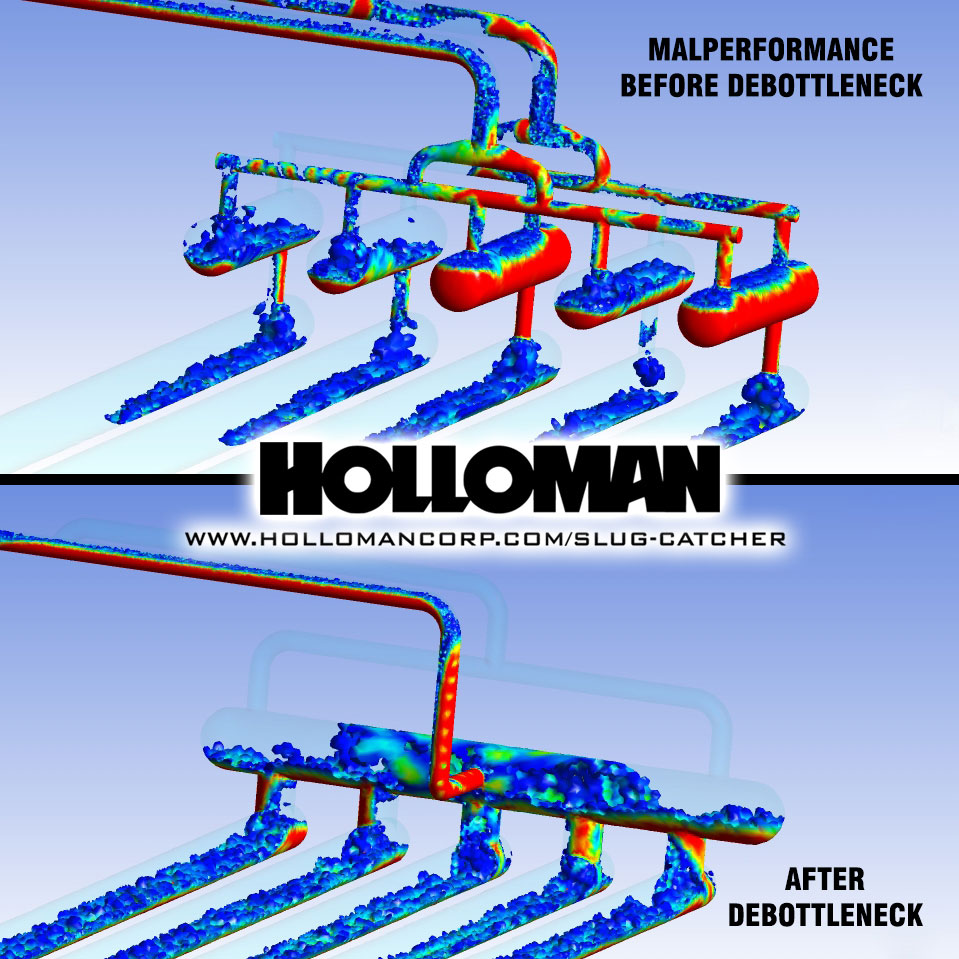

This brownfield harp / finger slug catcher debottleneck project was recently completed by Holloman for a Midstream Operator’s gas plant in West Texas. Holloman was engaged to evaluate options for addressing the chronic liquid carry-over problems that occurred when the plant’s existing slug catcher received pigs.

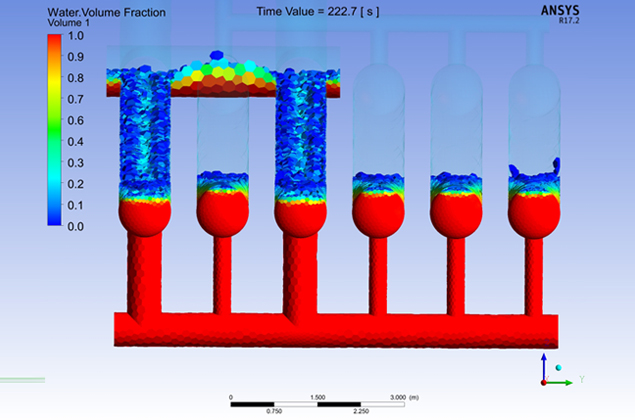

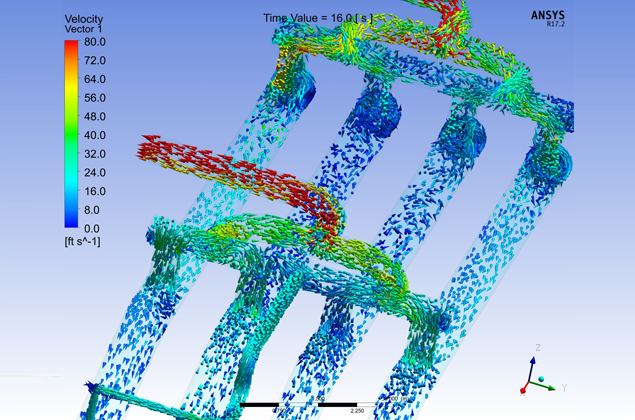

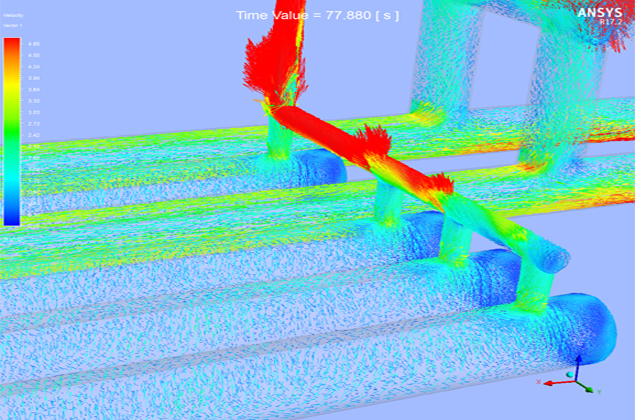

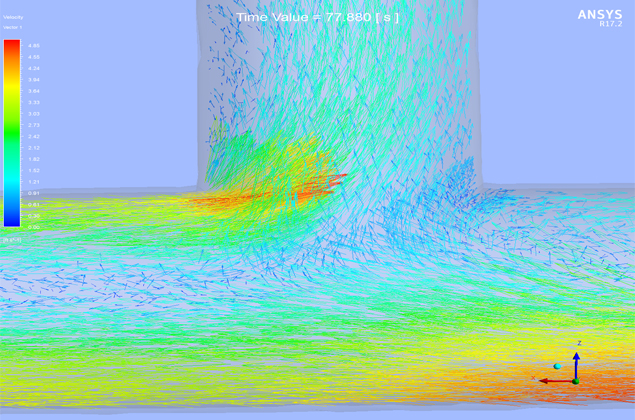

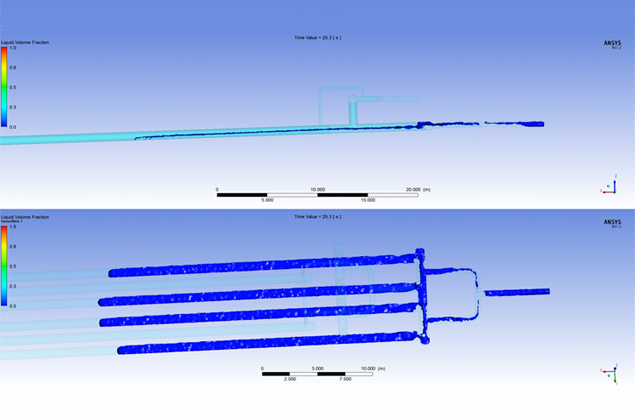

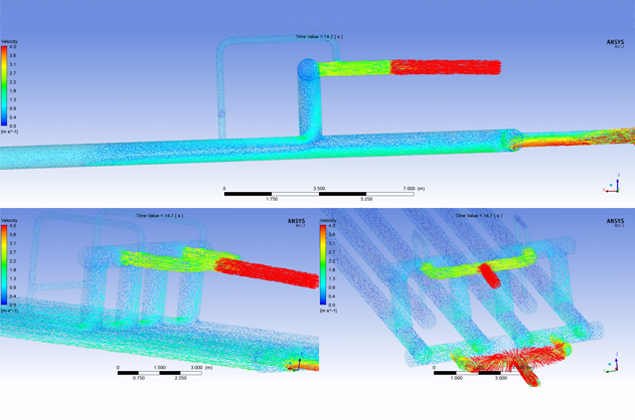

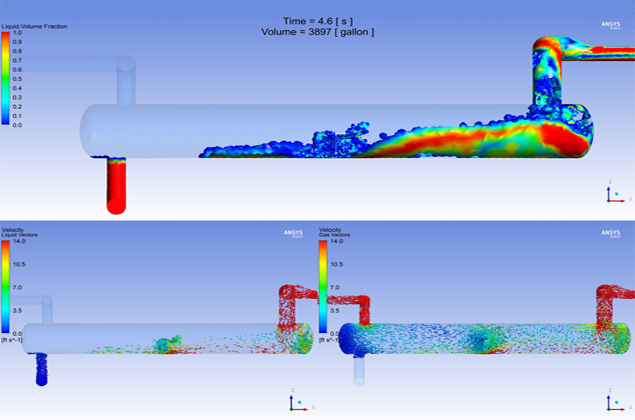

Holloman identified the root cause of the existing slug catcher’s liquid carry-over malperformance by conducting a Computation Fluid Dynamics (CFD) Performance Study. Holloman then proposed an expedited turn-key solution to replace the slug catcher’s inlet separation section and associated inlet/outlet piping, while keeping the existing finger piping and foundations in-place.

A complete laser-scan of the slug catcher and its surrounding area was used to fast-track the engineering and design process, as well as ensure the ultra-tight tolerance that was required for tie-ing in the replacement sections. The project was delivered ahead of schedule despite the challenges presented by brownfield construction. After it was commissioned, the debottlenecked slug catcher was able to receive incoming pigs at full speed without liquid carryover.

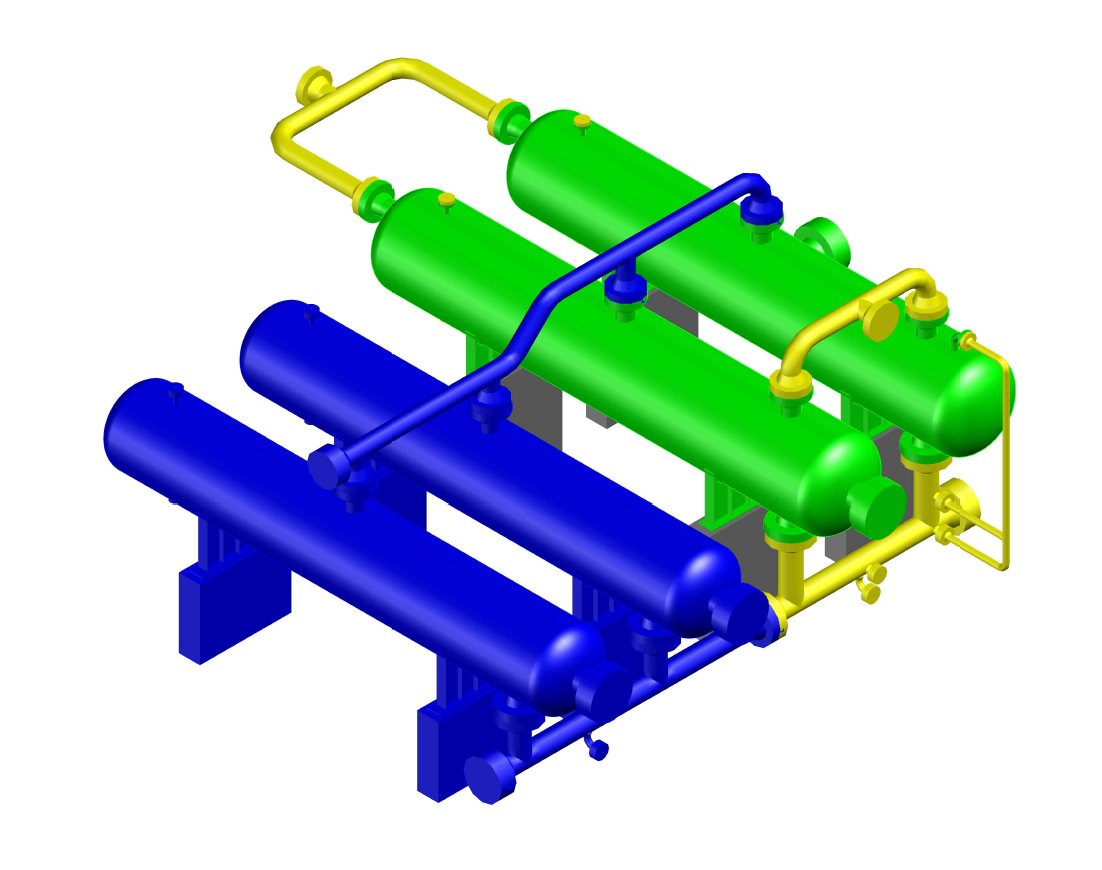

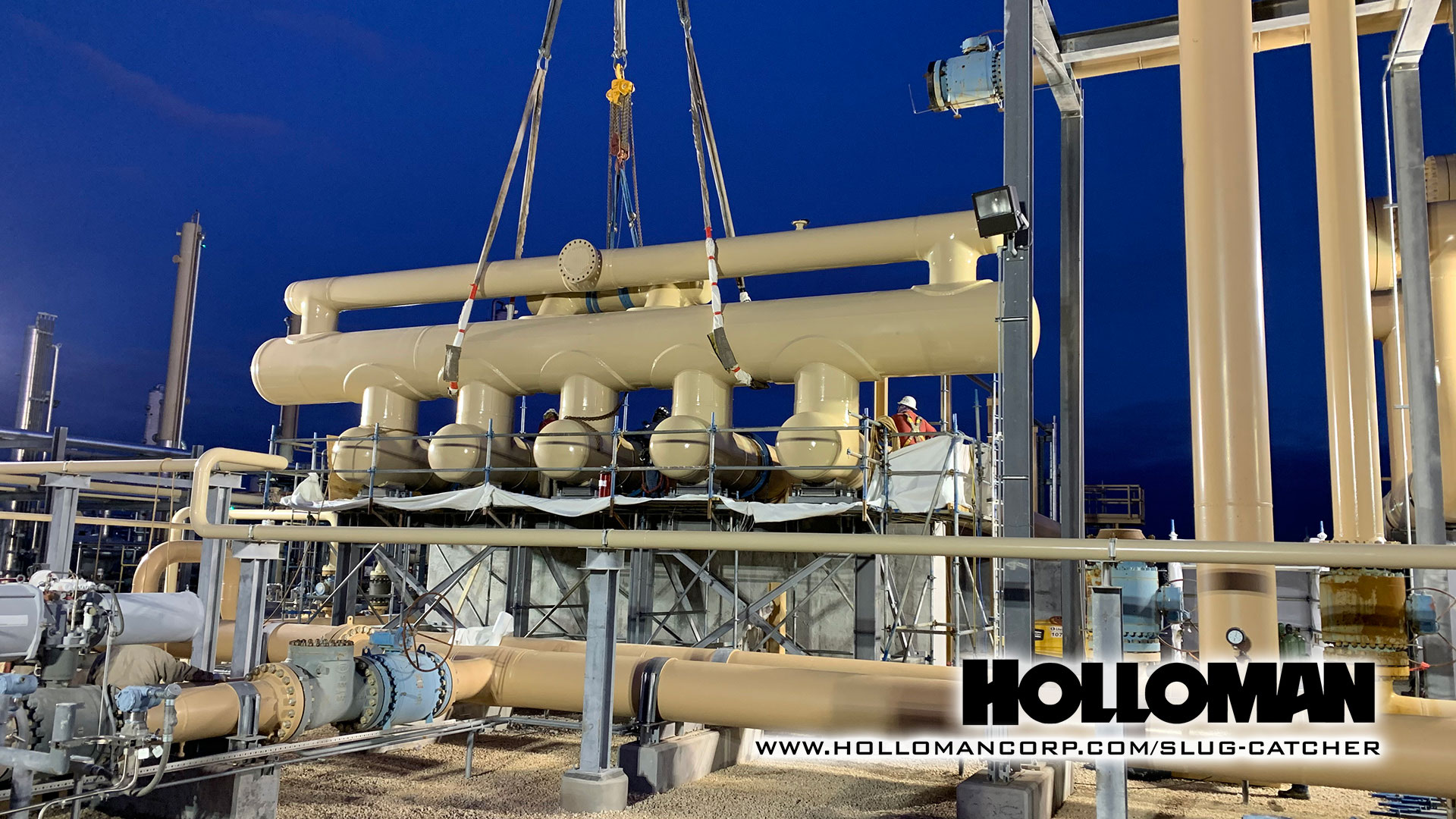

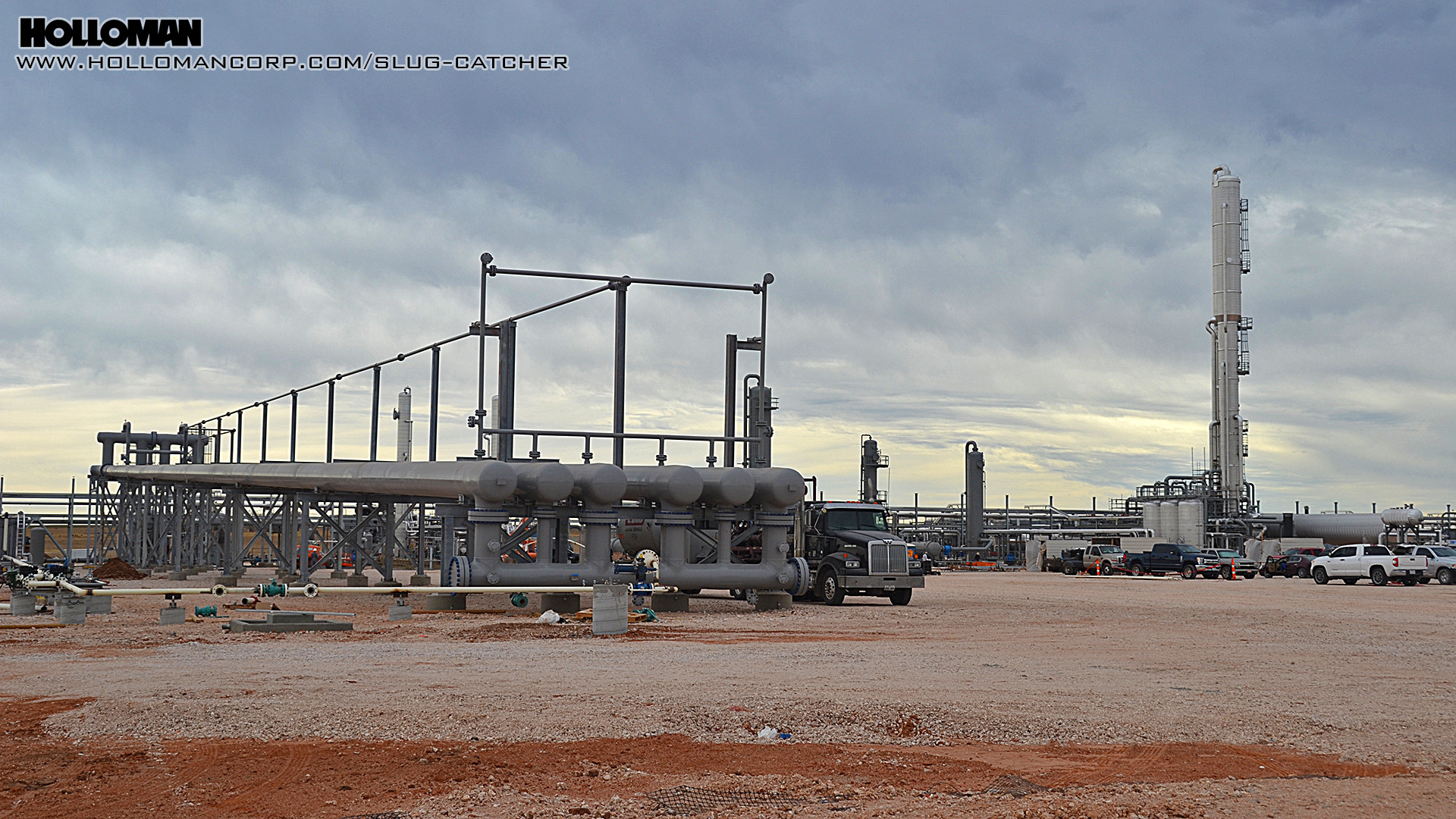

Construction has recently finished on this Holloman Engineered Products harp slug catcher package. This high performance 9,000 BBL design featured (10) fingers of 48” pipe with an overall length of 565 feet. Future expansion capability is provided with slots for (2) additional storage fingers.

This turn-key 8000 BBL harp / finger slug catcher was recently completed by Holloman for a major midstream operator’s gas plant in the Bakken shale play of North Dakota. This highly compact design featured (12) fingers of 54” pipe and was fully insulated and traced for low-temperature service.

This turn-key 2500 BBL harp / finger slug catcher was recently completed by Holloman for Canyon Midstream’s Redcliff Plant in the Oklahoma STACK play. The slug catcher’s versatile design can be expanded in the future to 5000 BBL with added liquid storage fingers.

Hollman completes 1000 BBL harp/finger slug catcher installation in the Permian Basin. Six finger design with 1440 PSIG rating utilizing modular flanged manifolds with field-welded fingers.